Loudspeaker Connectors: Weatherproof Solutions for Outdoor Venues

Outdoor venues demand speaker connectors that withstand rain, dust, and temperature changes. Reliable loudspeaker connectors like XLR speaker connectors and speaker cable connectors keep audio systems safe. Speaker terminal connectorshelp prevent corrosion. The right Speaker connectors ensure strong sound and protect equipment for years.

- Weatherproof designs improve durability and performance.

Key Takeaways

- Weatherproof loudspeaker connectors protect audio systems from rain, dust, UV rays, and temperature changes, ensuring long-lasting performance outdoors.

- Choose connectors with high IP ratings, durable materials like aluminum, and secure locking mechanisms to prevent corrosion and signal loss.

- Proper installation and regular maintenance, including cleaning and sealing, keep connectors reliable and extend their lifespan in harsh outdoor conditions.

Why Loudspeaker Connectors Must Be Weatherproof

Environmental Challenges in Outdoor Venues

Outdoor venues expose audio equipment to many harsh conditions. Humidity, temperature swings, and UV rays can damage connectors. Rain and snow cause moisture to seep into connection points. Over time, these factors lead to corrosion, cracking, and fading. Dust and debris also threaten the integrity of loudspeaker connectors. Outdoor sound systems use IP-rated weather-resistant technology to fight these problems. Sealed enclosures and special gaskets keep out water and dust. UV-resistant materials help connectors last longer under the sun. These features protect the system from rain, snow, and temperature extremes, ensuring reliable performance.

Tip: Always check local regulations before setting up outdoor sound systems. Use weather-resistant cabling and connectors to meet safety standards and prevent damage from environmental elements.

How Weatherproof Loudspeaker Connectors Provide Protection

Loudspeaker connectors designed for outdoor use offer several layers of defense. Manufacturers use materials like polyethylene and chlorinated polyethylene to block water, chemicals, and UV rays. These compounds prevent short circuits and corrosion, even when exposed to moisture and soil chemicals. Weatherproof connectors use silicone rubber gaskets or o-rings to create tight seals. Gold-plated contacts reduce oxidation and improve reliability. Locking mechanisms such as push-pull or screw locks keep connections secure. High IP ratings show resistance to water and dust. These design choices maintain signal integrity and reduce electrical hazards, even in extreme weather. Connectors like N and OSP types use threaded couplings and extra shielding to prevent signal loss and noise.

Choosing the Right Weatherproof Loudspeaker Connectors

Key Features: IP Ratings, Materials, and Locking Mechanisms

Selecting the right weatherproof loudspeaker connectors starts with understanding key features that affect performance and durability. The IP (Ingress Protection) rating, defined by the IEC 60529 standard, uses two digits to show how well a connector resists dust and water. For example, IP55-rated connectors offer solid protection against dust and water jets, but this rating only reflects short-term tests. Long-term outdoor use brings extra challenges like UV rays, saltwater, and temperature swings. Manufacturers often add UV-resistant materials, corrosion-proof hardware, and fiberglass enclosures to boost durability beyond what IP ratings alone can guarantee.

Material choice plays a big role in outdoor reliability. Aluminum, especially when CNC machined and anodized, stands out for its strength, corrosion resistance, and precise fit. It also shields against electromagnetic interference and handles heat well. Compared to wood or plastic, aluminum offers better mounting precision and connector fitment.

| Feature | Aluminum (CNC Machined) | Wood (MDF) | Plastic (Molded) |

|---|---|---|---|

| Mounting Precision | Very High | Moderate | Moderate-High |

| Mounting Strength | Very High | Moderate | Moderate |

| EMI/RFI Shielding | Excellent | Poor | Poor |

| Dimensional Consistency | Excellent | Fair-Good | Good |

| Connector Fitment | Excellent | Good | Good |

| Overall Integration Ease | High | Moderate | Moderate |

Locking mechanisms are essential for safety and reliability. Twist-lock and screw-lock designs keep connections secure, even when exposed to vibration or movement. Keyed connectors prevent mistakes during setup. These features help prevent accidental disconnections and maintain waterproof seals. ROXTONE, a trusted name in the industry, uses advanced locking systems and high-grade materials to ensure their loudspeaker connectors perform reliably in harsh outdoor environments.

Note: Always look for connectors with protective enclosures and Strain Relief to further enhance safety and durability.

Top Types: speakON, XLR, PowerCON, and Specialized Connectors

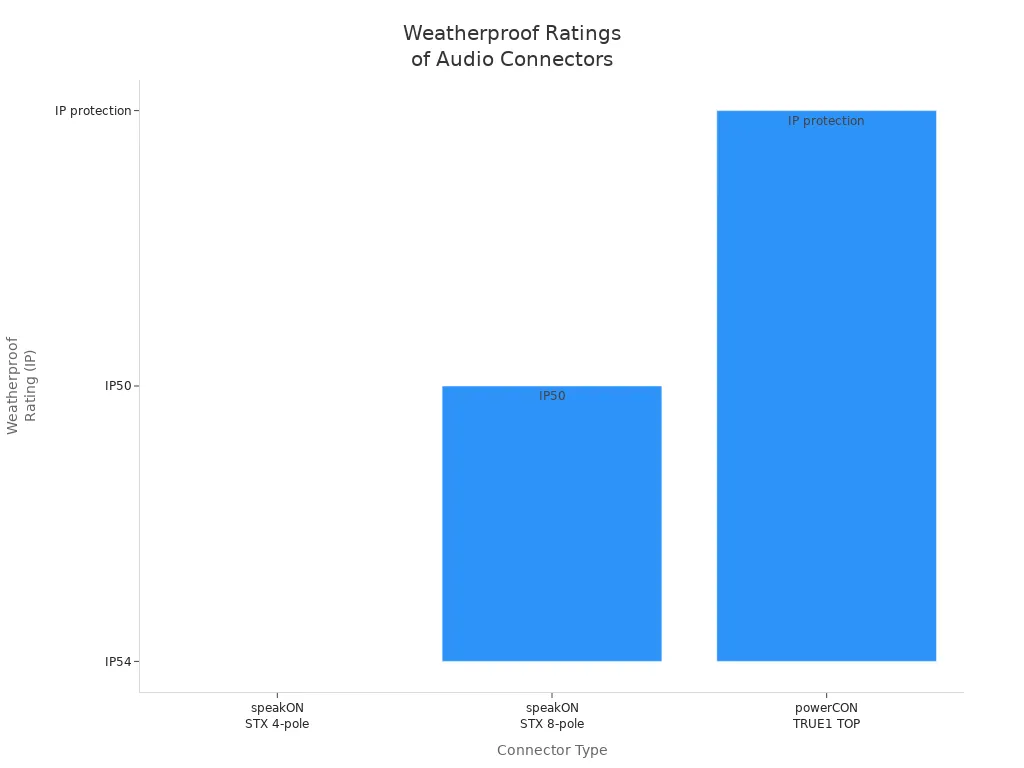

Different connector types offer unique benefits for outdoor venues. The speakON STX series, for example, provides IP54 or IP50 protection when fully mated. These connectors use a rugged twist-lock design, making them nearly indestructible and ideal for high-current speaker connections. PowerCON connectors, especially the TRUE1 TOP version, combine IP protection with UV resistance and are built for demanding outdoor applications. Standard PowerCON connectors, while robust, do not always carry explicit weatherproof ratings.

XLR connectors are common in audio setups, but standard versions lack specific weatherproofing. Some specialized loudspeaker connectors, like those used in marine or industrial settings, offer higher IP ratings and extra sealing features.

| Connector Type | Weatherproof Rating (IP) | Conditions / Notes | Additional Features |

|---|---|---|---|

| speakON STX 4-pole | IP54 | Achieved only when mated | Twist-locking, rugged, near-indestructible |

| speakON STX 8-pole | IP50 | Achieved only when mated | Same as above |

| powerCON (standard) | Not explicitly weatherproof rated | Robust locking AC power connector | No breaking capacity; not for connection under load |

| powerCON TRUE1 TOP | IP protection + UV resistance | Designed for demanding outdoor applications | Ruggedized sealed connectors, UL50E approved |

| XLR (standard) | Not detailed | No direct weatherproofing information provided | N/A |

| Specialized loudspeaker | Not detailed | No direct weatherproofing information provided | N/A |

ROXTONE offers a wide range of weatherproof loudspeaker connectors, including speakON and PowerCON options, designed for both performance and longevity in outdoor settings.

Installation and Maintenance Best Practices

Proper installation and regular maintenance keep loudspeaker connectors working at their best. Installers should use quick-connect branch cables and pre-stripped wire leads to reduce errors and limit exposure to moisture. Outdoor-rated jackets and weatherproof connectors protect against environmental damage. Color-coded plugs help assign speaker channels correctly, supporting a reliable setup.

Tip: Always install connectors facing downward, not upward, to prevent water from pooling and entering the connection.

Regular inspection is vital. Technicians should check connectors for signs of corrosion, dirt, or wear. Cleaning with a soft, damp cloth removes debris, while electronic contact cleaners help maintain signal quality. Silicone sealant around connection points adds another layer of moisture protection. Using weatherproof covers during storms or when equipment is not in use extends connector life.

Common mistakes can compromise weatherproofing. Failing to use sealing caps on unused connectors, modifying manufacturer-supplied rigging, or skipping drip loops in cabling can all lead to water ingress. Neglecting regular cleaning and inspection allows oxidation and debris to degrade seals and contacts.

Meyer Sound and other experts recommend periodic inspections tailored to local conditions. In harsh environments, more frequent checks and cleaning may be necessary. Adding rain hoods or installing speakers under shelter further protects connectors from the elements.

Alert: Warranty coverage for weatherproof connectors often depends on proper installation and maintenance. ROXTONE and other leading brands offer warranties ranging from two years to limited lifetime, but only when users follow recommended procedures.

Loudspeaker Connectors designed for outdoor venues deliver safety, reliability, and long-term performance. Industry trends show rising demand for weatherproof solutions. Proactive installation and maintenance maximize benefits:

- Assess site and select optimal locations.

- Apply waterproof seals.

- Clean and inspect regularly.

- Secure all cable connections.

FAQ

What does an IP rating mean for loudspeaker connectors?

An IP rating shows how well a connector resists dust and water. Higher numbers mean better protection for outdoor use.

How often should technicians inspect weatherproof connectors?

Technicians should check connectors before each event. In harsh environments, they should inspect and clean connectors every month.

Can standard indoor connectors work outside with covers?

- Covers help, but standard connectors still risk damage.

- Only weatherproof connectors provide full protection against rain, dust, and UV rays.

By: Roxtone

Tel: +86 574 87154705

Fax:+86 574 56138190

E-mail: [email protected]

Facebook: Roxtone

Youtube: Roxtone

X: Roxtone